What is Direct to Garment (DTG) Printing?

The direct to garment (DTG) process involves printing a digital image, directly onto natural fibre t-shirts, hoodies, tea towels, pillowcases, promotional products, caps/hats, or even shoes!

Direct to garment printers, also known as DTG printers or digital garment printers use special inkjet technology and are more economical, faster, and cleaner than traditional screen printing methods.

Getting started printing with DTG is really easy and requires significantly less operating space and business start-up costs.

When your business move into high-production mode, we recommended pairing your DTG solution with an automatic pre-treatment machine to improve productivity and ensure consistent pre-treatment of dark textiles.

Printers running higher volumes with multiple DTG printers should also consider investing in a tunnel dryer to improve curing productivity and result in a softer feel of the printed garment.

See our extensive range of DTG supplies

Direct to Garment (DTG) Printers

Pre-Treatment Machines

Direct to Garment Consumables, Accessories & Inks

Heat Transfer Presses

Tunnel Dryers

DTG printing applications

Print over zippers, seams and pockets

Customize different types of footwear (attachment required)

Personalize a variety of accessories

Print on jeans and denim

Print on the crown and bill of headwear (attachment required)

Simple steps to success

1 Create

Design your artwork on a computer

2 Pre-Treat if printing onto dark textiles

Use a spray system or an automatic pre-treatment machine to apply a layer of pre-treatment to the print area

3 Cure Pre-Treat if printing onto dark textiles

Heat press the pre-treated textile to bond the solution to the textile

4 Print

Print out the artwork directly onto your textile

5 Cure Print

Use a heat press or tunnel dryer to fix the printed ink. A tunnel dryer will result in a softer hand to the print textile

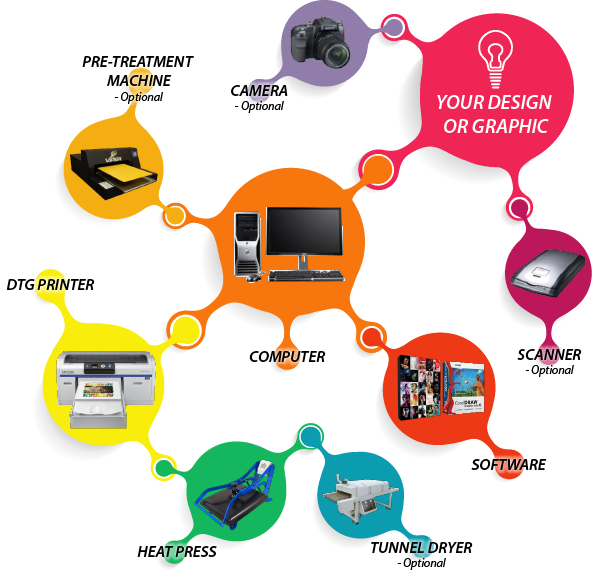

What do I need to get started in DTG?

How much does it cost to print a shirt on DTG printer?

| Expense | Cost |

|---|---|

| Dark T-Shirt | $5.00 |

| Inks | $4.03 |

| Pre-Treatment Solution | $0.35 |

| Labour | $0.65 |

| Maintenance | $0.40 |

| Total | $10.43 |

| Average Sell Price | $28.00 |

| Profit | $17.57 |

* Estimates only using a 35x40cm test image printed onto a dark garment using CMYK+W inks. All prices exclude GST.

What is the return on investment of a DTG printer?

Using the below points as an example you can potentially break even after just 10 months!

- Direct-to-Garment Printer value: $20,495

- Printing: 5 single-sided shirts a day for 5 days every week

- Average sell price: $30.00 each

* Estimates only and does not take into account your personal situation, overhead expenses and other variable costs. Please conduct your own calculations. All prices exclude GST.

Customer Success Stories

[VIDEO] The Tshirt Mill: taking the custom t-shirt world by storm

From humble beginnings selling designs at the local markets to a t-shirt printing powerhouse, The Tshirt Mill continues to go from strength to strength as it capitalises on the custom print revolution. And with a finger on the pulse of the music and festival scene, The Tshirt Mill is taking custom tees to the masses.

[VIDEO] Forza Italia captures customised print market in Melbourne

Forza Italia is Australia’s largest Italian retailer, importing a huge selection of well-known Italian brands including Ferrari and Juventus. With the help of GJS, it now also creates and personalises a variety of products on-demand in its Lygon Street store, as well as online via forzacustoms.com.au

Ready to get started?

If you're ready to seriously profit from the custom printed t-shirt market and create your own personalised products then click the button below and a GJS team member will be in touch to personalise a package that perfect for you!

![Case Study: [VIDEO] The Tshirt Mill: taking the custom t-shirt world by storm](https://res.cloudinary.com/gjs/image/upload/t_news_thumb,f_auto,q_auto:low/casestudy/9-video-the-tshirt-mill-taking-the-custom-t-shirt-world-by-storm60.jpg)

![Case Study: [VIDEO] Forza Italia captures customised print market in Melbourne](https://res.cloudinary.com/gjs/image/upload/t_news_thumb,f_auto,q_auto:low/casestudy/8-forza-italia-captures-customised-print-market-in-melbourne5.jpg)